BUSINESS

Mold development & production performance

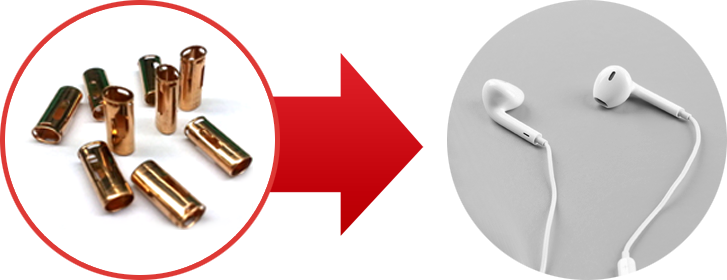

DEEP DRAWING

Possess mold development technology with precise deep drawing

Possess deep drawing molding technology and cam cutting technology that other press companies cannot imitate

Development and mass production of core deep drawing components tor earphone

Cathode Holder

Precision and small Deep Drawing

Small cylinder Φ1.57+20㎛

-10㎛

Cathode Cap

Drawling Thickness of base side : 0.160

Ground plan of floor : 10㎛

Thickness of side : 0.05±10㎛

Ni-Cup(For back light, CCFL)

Small cylinder Deep Drawing Technology

Measured values of external dimensions : Φ1.1×3, Φ1.3×3, Φ1.7×5

Case

Fine precise punching

Precise molding Drawing (Corner 0.03 Below)

Ground plan of floor : 10㎛

Coining (square) step at floor : 20㎛

True position of three holes : 0.01

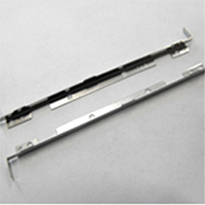

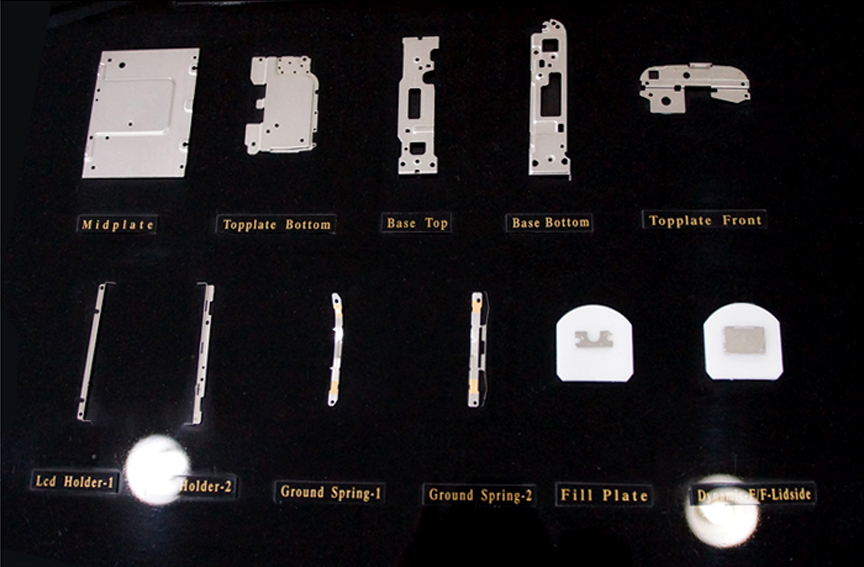

Mobile phone

Equipped with component development technology tor mounting in small mobile phone of complicated forms

Equipped with molding development technology for complicated forms

Precision measurement trend management

Quick turnover molding development technology

Molding design technology for various forms

notice board test[2017.02.24]